Server Room Protection in Hotels: A Corrosion Control Case Study

Published : 18 Jul 2025

INTRODUCTION

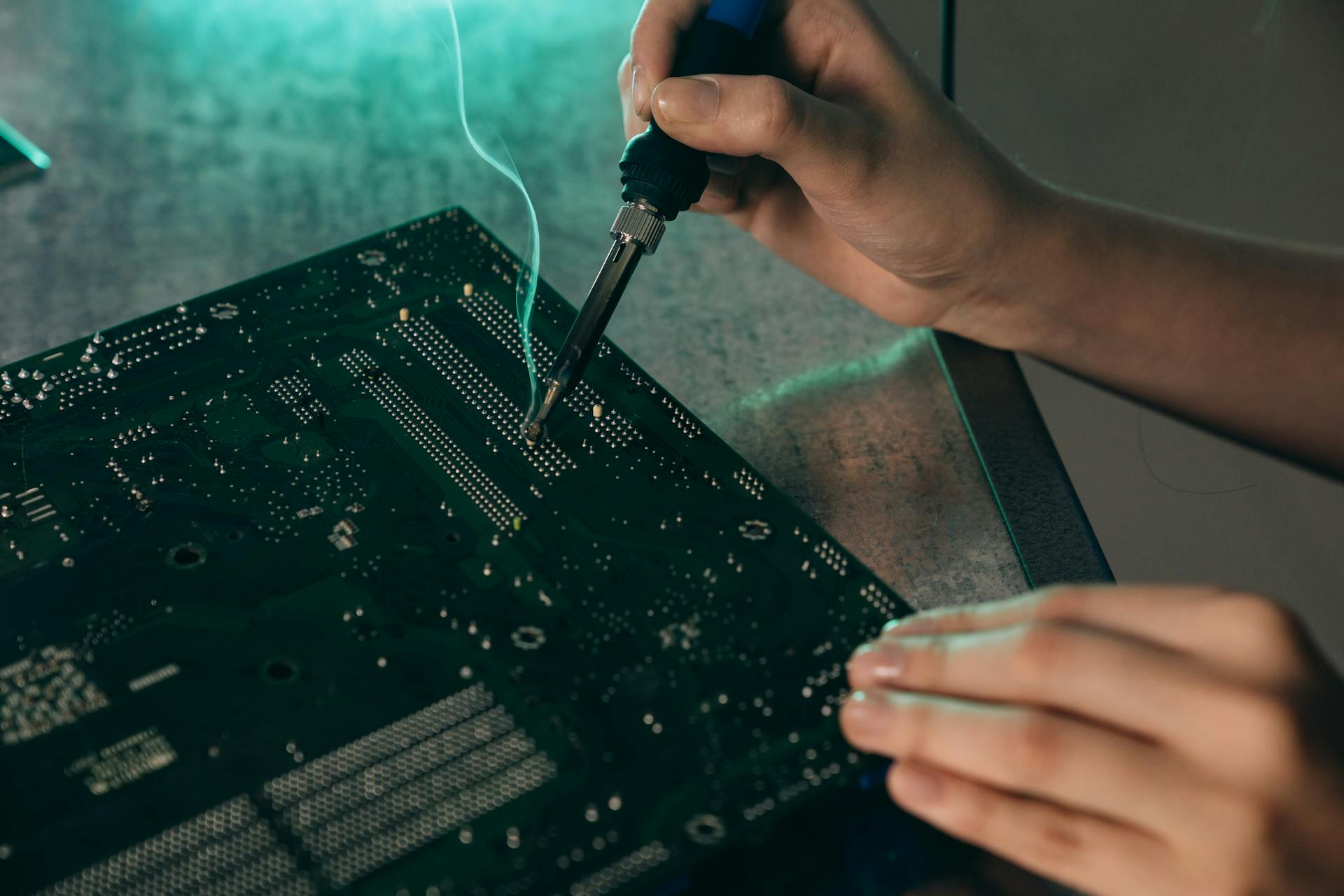

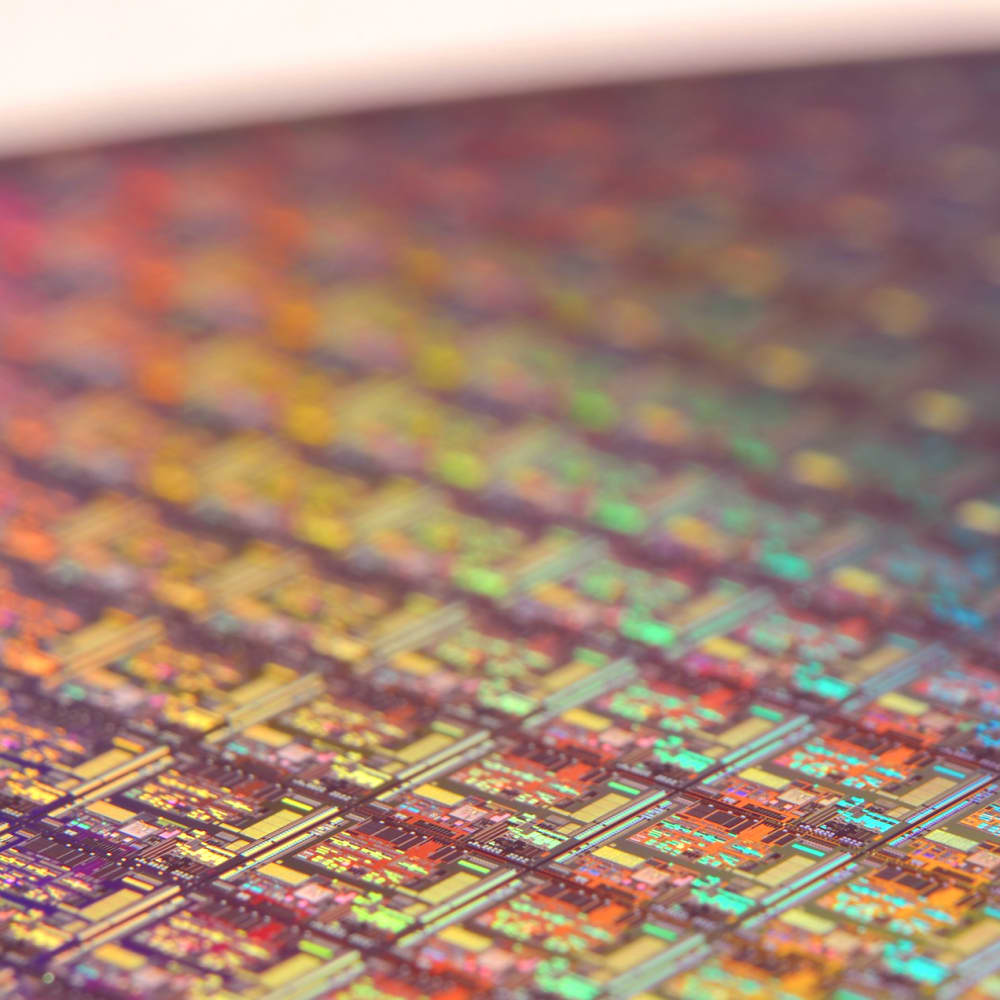

A prominent star hotel was experiencing frequent server room equipment failures, causing unexpected downtime and operational disruptions. The hotel relied on servers and PABX systems for its daily operations, but carbon like formation on server system boards and PABX components was severely affecting their performance and disruption in communication.

PROBLEM

The hotel's IT team conducted a corrosion monitoring assessment with the help of an external support, revealed critical risks to IT infrastructure, with copper corrosion at a severe level (Class GX), indicating a highly reactive environment, and silver corrosion at a moderate level (Class G2), showing signs of ongoing material deterioration. Additionally, the absence of a dedicated makeup air (DME) unit and reliance on two split AC units in the server room resulted in poor air quality control, leading to accelerated corrosion and equipment failures which further increased maintenance costs and caused higher OPEX for the hotel management. The hotel sought a reliable corrosion control solution to ensure long-term protection of its critical electronic assets to avoid any further operational disruption and prevent potential failures.

SOLUTION

Based on the server room size, environmental conditions, and corrosion monitoring data, a 500 CFM Corrosion Control Unit was installed and placed at the point where the incoming air interact with the server equipment, to ensure effective air purification. All gas infiltrates entering the server room—whether through inlet vents or carried in from external environments—are effectively captured and treated by the unit’s advanced three-stage filtration system before they reach any sensitive server equipment.

The process begins with a pre-filter, which captures dust and particulate matter from the air. The air is then directed by a fan through a gas-phase filtration stage, where highly efficient coconut based activated carbon media effectively adsorbs acidic gas molecules responsible for corrosion of server room equipment. Finally, a post-filter ensures the removal of any remaining micro-particles. The installed system effectively removed airborne contaminants, thus preventing further corrosion build-up or oxidise layer on sensitive electronic components protecting the PABX system from corrosion-related failures and reducing frequent repair cost.

RESULTS

Post installation of the corrosion control unit, the hotel observed significant reduction in corrosion-related failures of server and PABX systems. Leading to an extended lifespan of critical IT equipment and achieving OPEX savings by minimizing repair costs. Operational uptime significantly improved, allowing the system to be more stable and efficient. This ensured continuous performance with minimal disruptions caused by corrosion, keeping daily communications and operations uninterrupted.

CONCLUSION

By implementing the 500 CFM Corrosion Control Unit, the hotel successfully mitigated the risks associated with electronic corrosion and the formation of visible build-ups on equipment. The data related to humidity and temperature helps maintain the required environment inside the server room. This strategic approach to corrosion control, along with timely media replacement, continues to ensure a stable and reliable server environment, supporting uninterrupted hotel operations.

Ready to Prevent Costly Equipment Failures? Get in Touch Now

RELATED POSTS

- Risks associated with electronic corrosion

- AQOZA Corrosion Control Solutions and Products

- AQOZA Corrosion Monitoring Solutions and Products